Backyard Birds – Part 36

The last few weeks of working on the cabinet weren’t particularly interesting. I patched some little flaws on the marquetry door and on joints in the back. I built two shelves to go on the inside of the main cabinet compartment and made panels to be screwed into the back of the cabinet. I sanded every surface one last time.

All those tedious steps led up to one of my favorite things: Putting oil on the piece for the first time.

When I was working on my previous cabinet, my friend Bill suggested that I use tung oil to finish it. He gave me a sample to try, and I liked it and ended up using it on the whole piece. I decided to use tung oil again for this cabinet.

Tung oil is made from the seeds of tung trees, which are native to southern China. When it’s applied to a wooden surface, it seeps a little way into the wood fibers and dries to create a hard, glossy finish. The more coats of tung oil you apply, the shinier it will get. A piece that’s been finished with tung oil will still feel like wood, but very highly-polished wood.

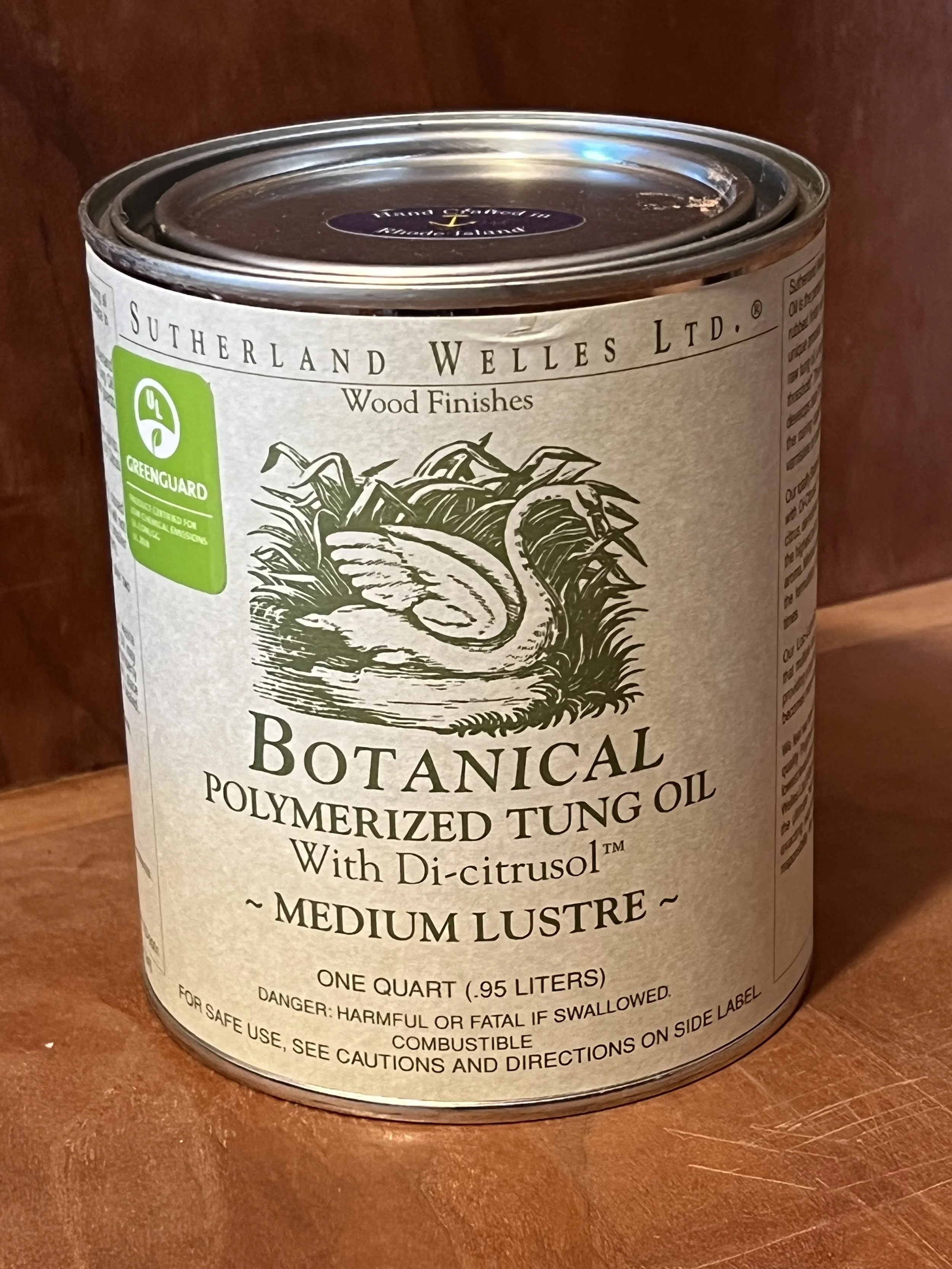

The product that I’ve been using is from a company in Rhode Island. It’s a polymerized tung oil with a citrus-based solvent added to it. It has a strong but pleasant orange scent. (This isn’t a sponsored post. I’ve just liked using this particular oil.)

Putting the first coat of oil on a piece is so exciting. The colors pop in a way that feels like magic, and all the detail of the wood becomes incredibly vivid. I took some videos of putting the first coats of oil on. Here is one of me putting the first coat on the marquetry door panel.

And here is one of me putting the first coat on the top of the cabinet, which is made of jarrah burl veneer and padauk.

As I talk about in the videos, in order to oil a piece, I first use a rag made from an old T-shirt to spread the oil over the surface. I let the oil soak in a bit, and then I wipe off the excess oil with a piece of cloth napkin in order to prevent it from getting sticky. Then I wait 24 hours and repeat the process.

Tung oil, like most finishing substances, is flammable, so when I’m done with the rags, I lay them out on the floor of the lacquer spray room where there is a fire suppression system. I also wear nitrile gloves while working with tung oil. Some tung oil can actually be food-safe if it’s cured for long enough (check the product you’re using to see if and under what circumstances it’s food-safe), but it’s not great to get it all over your skin when you’re applying it.