Backyard Birds – Part 31

For the bottom of the drawer of the cabinet, I wanted to make a trompe-l'œile pile of birdseed. Instead of making veneer like I did for the bird feeder in my marquetry panel, I decided to try a different method.

I cut up a bunch of veneer scraps to make “birdseed,” the same way that I did for the bird feeder.

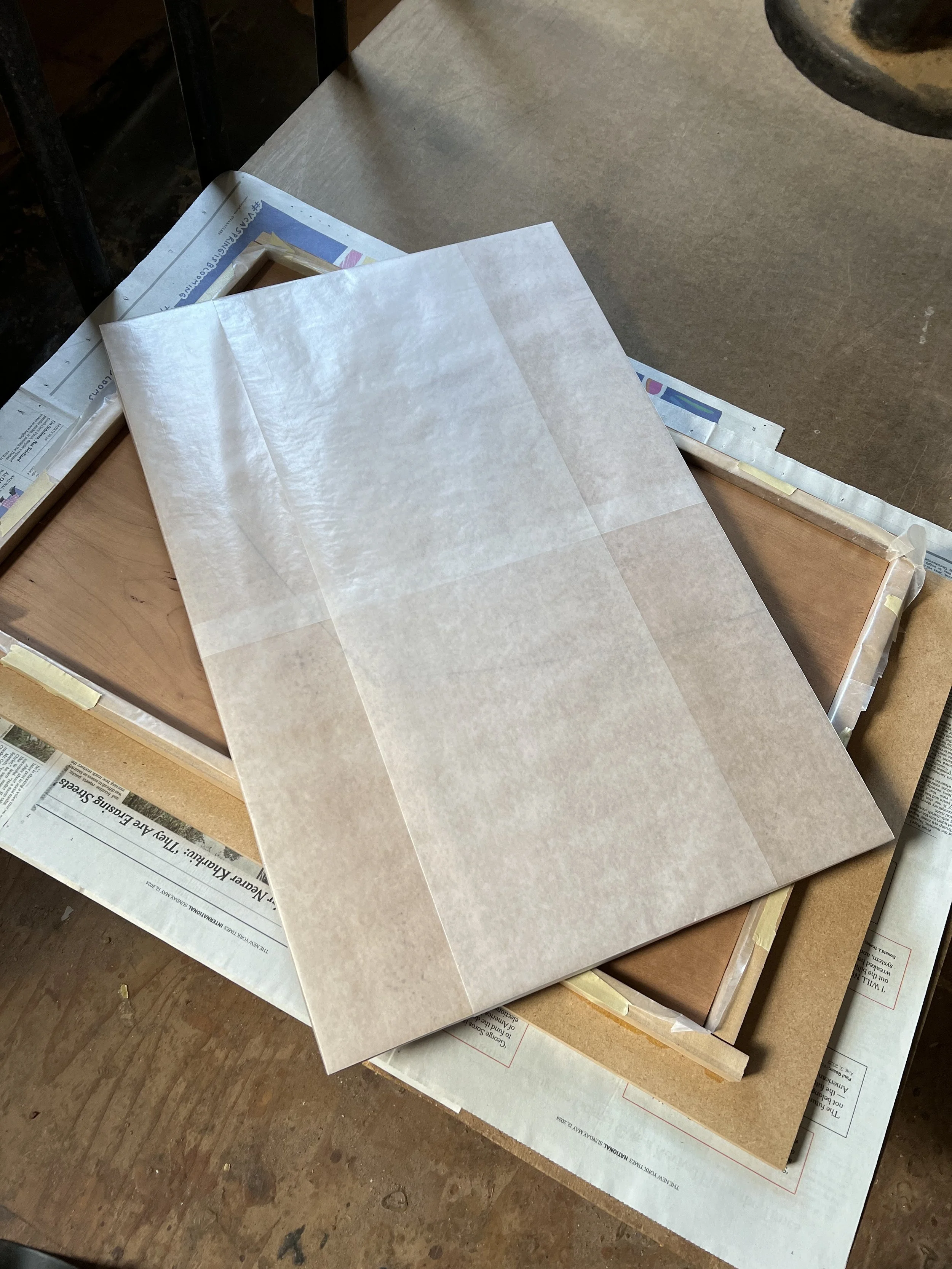

I also built a bigger tray out of fiberboard, similar to the one that I made to make birdseed veneer, and lined it with wax paper.

I prepared a drawer bottom by gluing veneer to both sides of a 1/8th inch piece of plywood. The drawer bottom fit snuggly in the tray.

I cut another piece of fiberboard to fit on top of the drawer in the tray and lined that with wax paper too.

I poured a large amount of epoxy over the drawer bottom in the tray, and then poured the veneer “birdseed” in a pile in the epoxy.

I fitted the wax paper-covered board on top of the tray and put the whole thing in the press overnight.

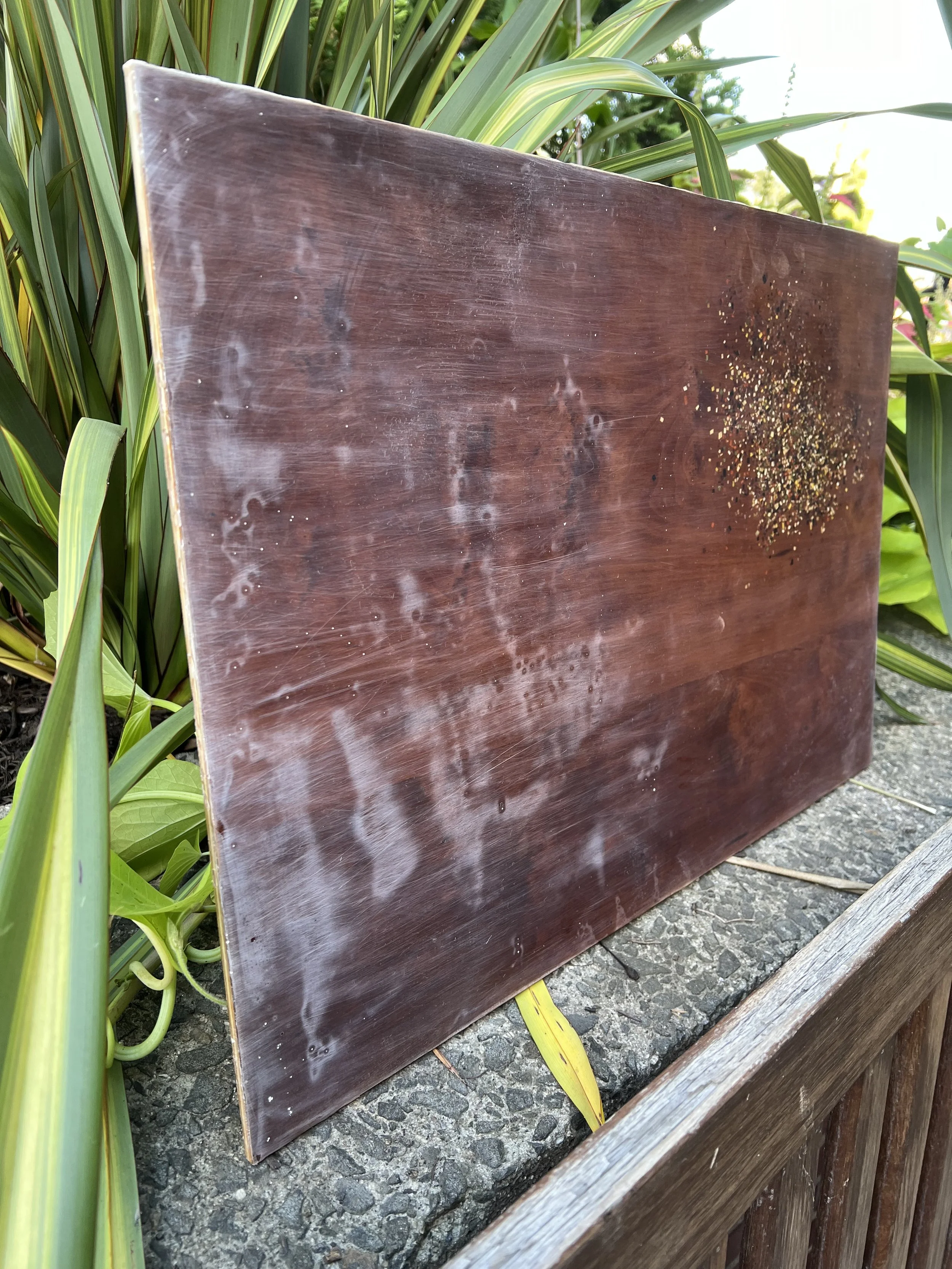

The next morning, the epoxy had dried, but it hadn’t pressed evenly, and it had a wrinkled appearance.

That wasn’t surprising, but it meant I’d have to do a lot of sanding and more coats of epoxy.

The unevenness of the epoxy made it especially hard to sand, and on the first try, I ended up sanding all the way through the epoxy to the veneer below several times. The coarse-grit sandpaper also made the epoxy cloudy.

I applied another coat of epoxy, as well as a bit more birdseed to cover some bare spots. The result was better, but the epoxy was not smooth and had a slightly pebbled texture.

I ended up applying four coats of epoxy in total and sanding the drawer after each coat with a coarse grit sandpaper. I went through a lot of sandpaper because the epoxy residue would stick to the sandpaper and make it gummy.

After the fourth coat, I sanded the drawer with 80 grit sandpaper (coarse), then 120 grit (medium), then 220 grit (the finest grit that I usually use on wood). That still left the epoxy cloudy, so I moved on to even finer grits. I also wet sanded the epoxy, using a special type of sandpaper that I dipped in water before using it. But the epoxy was still cloudy.

Finally, I scrubbed at the drawer with steel wool. This was probably my least favorite part of the entire process of making the cabinet. The tactile sensation of epoxy dust on steel wool is pretty horrific, and I spent a whole day working on it. But it worked. Hours of scrubbing ground out all the tiny grooves in the epoxy that were causing the cloudiness, and the drawer bottom finally had a smooth, even sheen.